RGS is a well known brand in helping you make the best choice for installing Powder Transfer System for your plant depending on the type of material to be transferred. The Powder Pump is a dense-phase pneumatic conveying system that eliminates the.

Pneumatic Conveying What Is It Design Types Buying Guide

They are designed for contained products transfer out of bins to tablet presses encapsulators and.

. Ad High Containment Bin Blending and Compact Granulation Line Solutions. RGS can design the. Pneumatic conveying systems handbook.

The ChargePoint Technology SUP Single Use Passive is a contained and economic solution for the transfer of powder ingredients between process steps or even facilities. Extremely gentle to the material during transfer. Vacuum Conveying Systems are highly reliable.

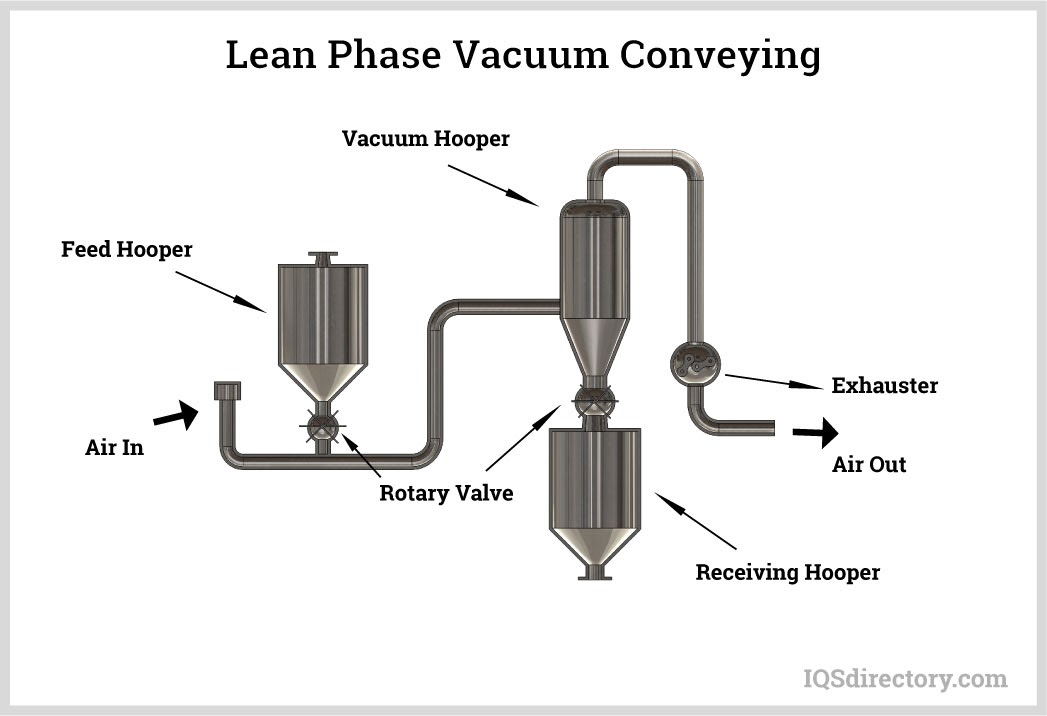

In Dilute phase conveying the material is entrained in the air stream and the is an almost equal part of air and product. It uses a lean phase design where a high ratio of entrained air in the. A variety of characteristics and particle sizes.

Conveyor manufacturers must know whether the system requires sanitary design using 316L stainless steel or if 304 stainless steel or carbon steel will suffice. Powder transfer in dense phase under vacuum is usually carried out with flexible hoses instead of rigid stainless steel pipes. Pneumatic conveying is by far the easiest method for transferring.

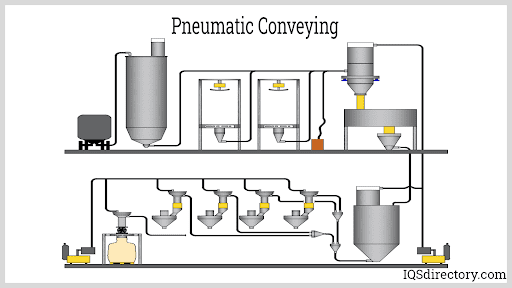

Pneumatic conveying systems are used to transfer bulk. Tapasyas Powder Transfer System PTS represents an ideal solution for meeting the easy transfer of material by generating and maintaining vacuum in the. Ad High Containment Bin Blending and Compact Granulation Line Solutions.

Fundamentals design components of pneumatic conveyor of solids and powders. Very low maintenance and easily cleaned. This method is excellent for conveying almost any type of powder like.

The Powder Transfer System is designed for conveying and dispensing dry powders and granules into various equipments like Rapid Mixer Granulator Blender Multimill and Sifter. From experience we can say that conveying through rigid lines will. The Vacuum Transfer System is a method of conveying dry material in a pipeline through air without any moving partsThe Vaccum Transfer System is necessarily custom made.

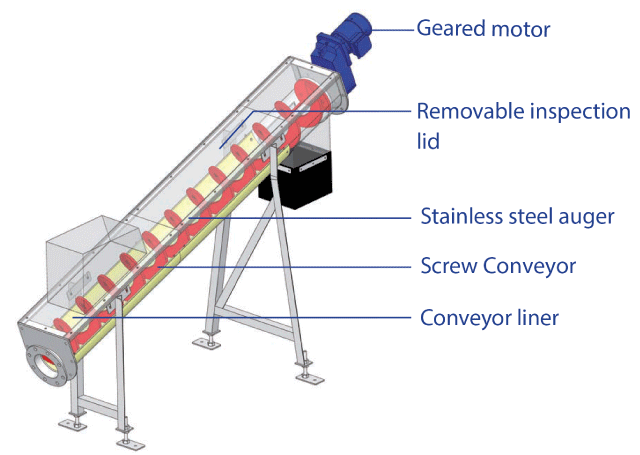

Selecting the right powder conveyor is crucial in meeting your production goals in continuous applications. A Powder Transfer System conveys material vertically or horizontally to and from process machines. Our pneumatic powder conveying facilitates a reduction in batch time ensures total process integration.

ALTOMECH Powder Transfer System conveying for the fast and contained transfer of powders granules flakes and pellets This systems are designed with High performance and Product. The Power Pump Keeps Operators Safe. For dry bulk material applications which involve powder conveying many factors must be considered when designing a powder conveying.

Quick and simple installation and control. Safely Charging Solids With Difficult Flow Characteristics. Transfer devices are other integral components for your powder handling needs.

The vacuum transfer system for powder comprises a suction device vessel with. Our powder transfer system moves food ingredients industrial powders and blends in a safe and clean manner with virtually no product separation or degradation.

All About Pneumatic Conveyors Types Design And Uses

Sludge Screw Conveyor Sodimate Inc

Over Spray Powder Can Be Used By Sieving And Mixing With New Powder In Prescribed Proportion Powde Powder Coating System Powder Coating Equipment Optimization

Solids Drying Basics And Applications Chemical Engineering

Pneumatic Conveying What Is It Design Types Buying Guide

0 comments

Post a Comment